Elevate Your Print: The Unseen Power of Varnish in Finishing

In the world of printing, the final touch can make all the difference. While vibrant inks and striking designs capture attention, it’s often the subtle yet sophisticated application of varnish that truly elevates a printed piece, offering both protection and an undeniable aesthetic appeal. At Ewan Printing, we understand that every detail counts, and that’s why we champion the versatile power of varnish.

What is Varnish in Printing?

Think of varnish as a clear, transparent coating that’s applied to your printed materials, much like an extra layer of ink – but without pigment. It’s essentially a liquid applied either during the printing process or as a separate finishing step. Its primary purpose is twofold: to protect the printed surface and to enhance its visual and tactile qualities.

Composed typically of resins, drying oils, and solvents, varnish dries to form a hard, clear film that acts as a barrier, shielding your print from the wear and tear of daily handling, smudges, scuffs, and even moisture.

The Different Faces of Varnish:

Varnish isn’t a one-size-fits-all solution. Different types offer distinct finishes and benefits, allowing for a wide range of creative possibilities:

- Gloss Varnish: This is perhaps the most common type, providing a high-shine, reflective surface that intensifies colors and adds a luxurious, vibrant look. It’s excellent for making images pop and creating a polished, professional appearance, often seen on brochures, magazine covers, and product packaging.

- Matte Varnish: In stark contrast to gloss, matte varnish delivers a smooth, non-reflective, and subdued finish. It exudes elegance and sophistication, making it ideal for high-end publications, corporate reports, or any piece where a refined, understated aesthetic is desired. Matte varnish also helps reduce glare, making text easier to read.

- Satin Varnish: Striking a perfect balance between gloss and matte, satin varnish offers a moderate sheen and a soft, smooth texture. It enhances durability without being overly reflective, providing a sophisticated yet practical finish for a wide array of printed materials, from book covers to business cards.

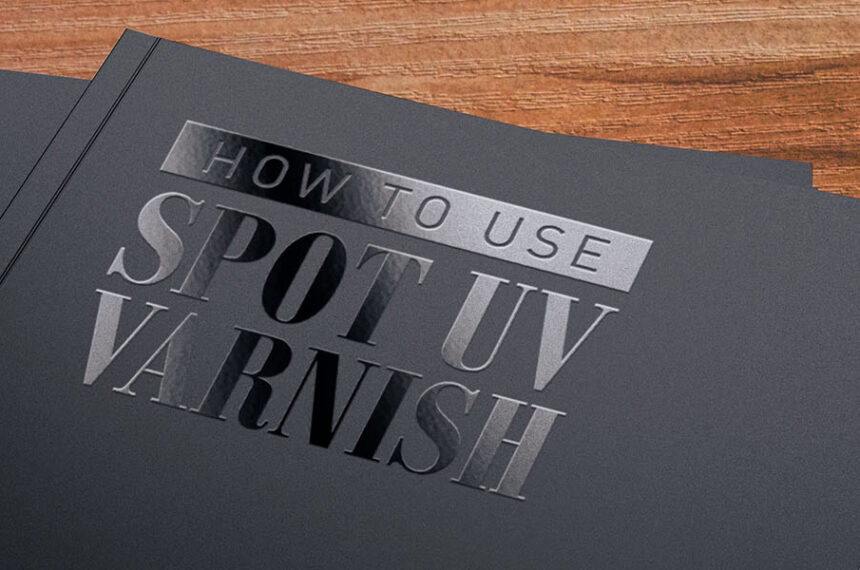

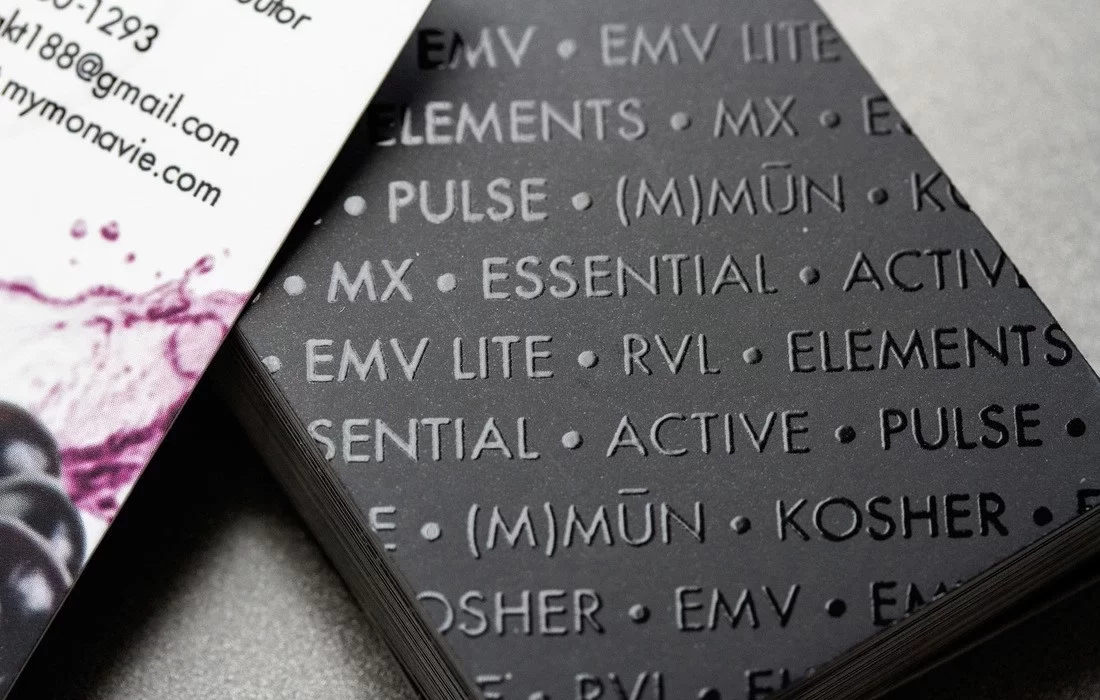

- Spot Varnish: This technique is where varnish truly becomes a design element. Instead of coating the entire surface (known as “flood varnish”), spot varnish is applied only to specific areas of the printed piece. This creates a compelling contrast between glossy and non-glossy areas, drawing attention to logos, images, or key text, adding depth and a tactile dimension to the design. Imagine a matte background with a glossy logo that subtly catches the light – that’s the power of spot varnish.

- UV Varnish: This is a high-performance option. UV varnish is applied as a liquid and then cured instantly using ultraviolet (UV) light. This process creates an exceptionally durable and often ultra-glossy finish, offering superior resistance to scuffs, scratches, and wear. It’s a popular choice for materials that will experience heavy handling, such as premium packaging or outdoor displays.

The Benefits of Varnish: More Than Just a Pretty Finish

Choosing to apply varnish to your print project offers a multitude of advantages:

- Enhanced Protection: Varnish acts as a protective shield, safeguarding your printed materials from fingerprints, smudges, scuffs, and even minor moisture damage, significantly extending their lifespan.

- Aesthetic Appeal: From the eye-catching brilliance of a gloss finish to the refined elegance of a matte look, varnish dramatically enhances the visual appeal of your printed pieces, making colors appear richer and more vibrant.

- Tactile Experience: Certain varnishes, especially soft-touch and spot applications, can add a unique tactile dimension, inviting interaction and creating a memorable sensory experience for the recipient.

- Brand Reinforcement: Consistent use of varnish finishes can contribute to your brand’s overall identity, creating a cohesive and professional look across all your printed collateral.

- Cost-Effectiveness: While adding a finishing step, varnish can be a cost-effective way to enhance durability and perceived value compared to other protective coatings like lamination.

Partnering with Ewan Printing for Your Varnish Needs

At Ewan Printing, we understand the art and science of print finishing. Our expertise in applying various types of varnishes, whether for a protective flood coat or a sophisticated spot application, ensures your projects achieve their full potential. We work closely with you to select the ideal varnish that aligns with your design vision, budget, and the intended use of your printed materials.

Don’t let your print simply exist. Let it impress. Explore the world of varnish with Ewan Printing and give your designs the flawless finish they deserve.

The most trusted and quality printing company, with excellent customer service. Best Quality Printing in Dubai

#EWANPRINTING

WhatsApp/Call us:

Arabic: 055 5771552

Arabic & English: 056 5071752 – (Send Query) https://wa.me/message/ZCPEMGR67ZD6G1

English | Urdu | Hindi: 050 508 6855

For latest offers

Email: printingewan@gmail.com

Location: Shop 26 and 28, Al Nasiriya Building, 247 Damascus Street, Al Qusais Industrial Area 1, Dubai, UAE

Leave a Reply