The Mark of Professionalism: Exploring the Art of Perfect Binding

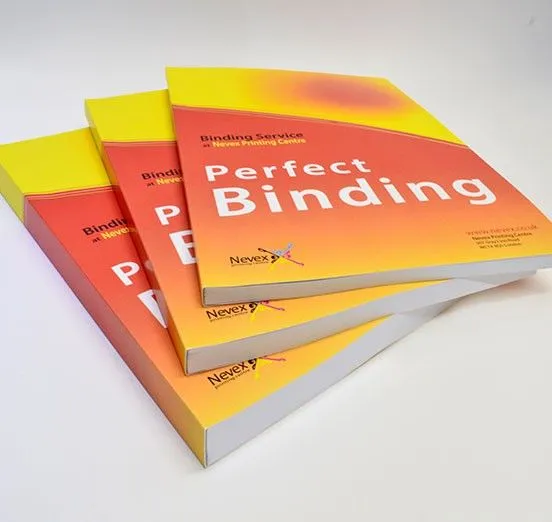

In the vast landscape of printed materials, the way a document is bound speaks volumes about its quality and professionalism. Among the most popular and aesthetically pleasing methods, perfect binding stands out as a sophisticated choice for creating books, magazines, catalogs, and reports that demand a polished, durable finish.

At Ewan Printing, your trusted printing partner in Dubai, we frequently employ perfect binding to transform stacks of individual pages into beautifully cohesive and enduring publications.

What is Perfect Binding?

Perfect binding is a softcover binding method where the interior pages of a document are gathered, stacked, and then roughed up along the spine edge. A strong, flexible adhesive (typically hot-melt EVA or more durable PUR glue) is then applied to this roughened spine. A pre-scored cover, usually made of heavier cardstock, is wrapped around the glued page block and firmly pressed into the adhesive. Once the glue cures, the three open edges of the book are precisely trimmed, resulting in the clean, square, and “perfect” edges from which the method derives its name.

This process creates a flat, printable spine, which is a key advantage, allowing for titles, author names, or branding to be displayed when the book is shelved.

The Perfect Binding Process: A Closer Look

The creation of a perfect bound document involves several critical steps:

- Page Gathering (Collating): All the interior pages are accurately collated and stacked in the correct order.

- Spine Preparation: The spine edge of the compiled page block is roughened, often by grinding or milling. This creates a textured surface that allows the adhesive to penetrate deeper into the paper fibers, ensuring a stronger bond.

- Adhesive Application: A thin, even layer of specialized hot-melt glue is applied to the prepared spine.

- Cover Application: The pre-scored cover is carefully wrapped around the glued page block and pressed firmly onto the adhesive.

- Curing: The glue is allowed to cure and set, forming a strong and flexible bond that holds all the pages securely to the cover.

- Trimming: Finally, the three remaining untrimmed edges (head, foot, and face) of the book are precisely trimmed to create clean, crisp edges, giving the perfect bound book its characteristic sleek appearance.

Why Choose Perfect Binding?

Perfect binding offers a multitude of benefits that make it an ideal choice for a wide range of publications:

- Professional and High-End Appearance: The flat, square spine and clean edges give perfect bound documents a sophisticated, book-like finish that conveys quality and attention to detail.

- Printable Spine: A significant advantage is the ability to print text, logos, or designs on the spine, making it easy to identify the publication when it’s on a bookshelf or stacked.

- Durability: When properly executed with quality adhesives, perfect binding creates a robust and durable bind that can withstand frequent handling and last for years.

- Accommodates High Page Counts: Unlike saddle stitching, perfect binding is suitable for documents with a significant number of pages, typically ranging from around 28 pages up to several hundred. The thickness of the spine can accommodate a considerable volume of content.

- Versatility: It’s a versatile binding method suitable for various applications, including:

- Paperback books (novels, non-fiction)

- Magazines and journals

- Catalogs and brochures

- Annual reports and corporate documents

- Manuals and guides

- Cost-Effective for Larger Runs: While often more involved than saddle stitching, perfect binding becomes increasingly cost-effective for larger print quantities due to economies of scale in the production process.

Considerations for Perfect Binding

While highly advantageous, there are a few points to consider when opting for perfect binding:

- Minimum Page Count: Due to the need for a sufficiently wide spine for the glue to adhere effectively, there’s usually a minimum page count (often around 28 pages, depending on paper thickness) required for perfect binding.

- Does Not Lay Completely Flat: Unlike spiral or wire-o binding, a perfect bound book will not lay completely flat when opened, which might be a consideration for manuals or cookbooks where hands-free reading is desired.

- Spine Creasing: With heavy use, the spine of a perfect bound book may show signs of creasing, particularly if the paper or cover stock is not adequately suited for the application.

Ewan Printing: Your Partner for Perfect Bound Publications in Dubai

At Ewan Printing, we leverage advanced perfect binding machinery and a team of skilled professionals to deliver impeccably bound publications. We understand the nuances of paper weight, adhesive types (including robust PUR for enhanced durability), and precise trimming to ensure your perfect bound projects not only look exceptional but also stand the test of time.

Whether you’re looking to publish a new book, create a compelling corporate report, or produce a high-quality magazine, perfect binding offers a professional finish that elevates your message. Contact Ewan Printing today to discuss your perfect binding needs and discover how we can help you create a lasting impression with your printed materials.

The most trusted and quality printing company, with excellent customer service. Best Quality Printing in Dubai

#EWANPRINTING

WhatsApp/Call us:

Arabic: 055 5771552

Arabic & English: 056 5071752 – (Send Query) https://wa.me/message/ZCPEMGR67ZD6G1

English | Urdu | Hindi: 050 508 6855

For latest offers

Email: printingewan@gmail.com

Location: Shop 26 and 28, Al Nasiriya Building, 247 Damascus Street, Al Qusais Industrial Area 1, Dubai, UAE

Leave a Reply